Whisk Away

It is evident that the Japanese tea ceremony is as much about the celebration of artisan craftsmanship and finely engineered tools – on which it must be said that the tradition remains firmly founded – as it is about celebrating the pleasures of tea itself.

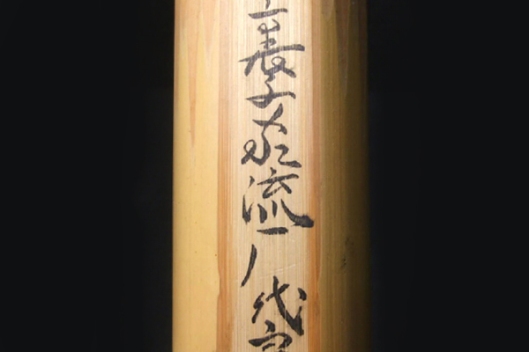

The chasen, perhaps more well-known by the less cryptic term, bamboo whisk, is one such tool.

Carved from a single section of bamboo, this finely handcrafted tool is made by splitting fibres of a short bamboo column into distinct, curled whiskers to form the 100 odd stiff, upright arms that extend from the handle of the whisk and are used to stir the tea.

In admiration for this aged old masterful craft we have outlined the 8-step process by which these marvellous whisks are fashioned by the Takayama whisk makers of Ikoma city in Nara prefecture.

1. RAW BAMBOO

A 2-3 year old piece of white bamboo, after being harvested in early winter, is boiled, cleaned and bleached in the sun to strengthen and harden the raw bamboo.

2. INITIAL SHAPING

The upper half of a whisk-sized bamboo piece is then peeled, and divided into 12-24 equal parts (depending on the thickness of the bamboo) using a sharp knife.

3. FINER CUT

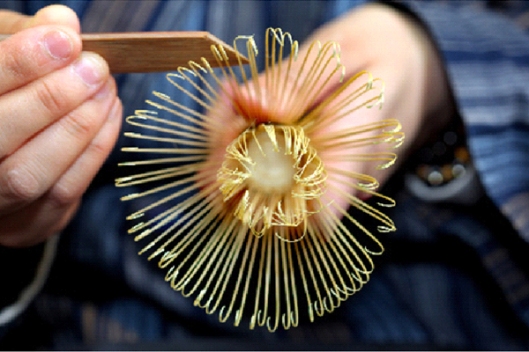

The 16 parts are then each divided into 10 equal spines to create a whisk with a total of 160 whiskers – in the case of a 80本立 chasen. Of the 160 spines, half will be used to form the outer splayed layer of whisk, and the other half to form the inner bundle of spines.

4. SHAVING

The bamboo arms are then softened in hot water and pared from bottom to top. Once suitably thin, the arms are ironed and reshaped.

Depending on the number of arms, a chasen can be suited to different roles. For instance, when making koi cha – or thick matcha, a chasen with less spines is more suitable; whereas when making usu cha – thin/weak matcha, a chasen with more spines would be preferred.

5. MOLDING

Each whisker on the chasen is then individually shaved to taper the edges, which helps to prevent lumps of tea from sticking to the arms of the whisk.

6. INNER & OUTER SHAPING

Using a fine piece of string, the whiskers are then divided into their separate inner and outer layers.

7. FINAL SHAPING

A bamboo spoon is then wedged in-between the inner and outer layers, creating the desired angle of splay between the two layers.

8. FINISH

The final corrections to the spacing and form of the individual spines is made.